The Dawn of a New Manufacturing Era

3D printing, also known as additive manufacturing, is revolutionizing the way we create objects, from simple household items to complex industrial components. This technology builds objects layer by layer, offering unparalleled flexibility in design and production. As we delve into the capabilities and future potential of 3D printing, it's clear that this innovation is not just a trend but a cornerstone of modern manufacturing and design.

How 3D Printing Works

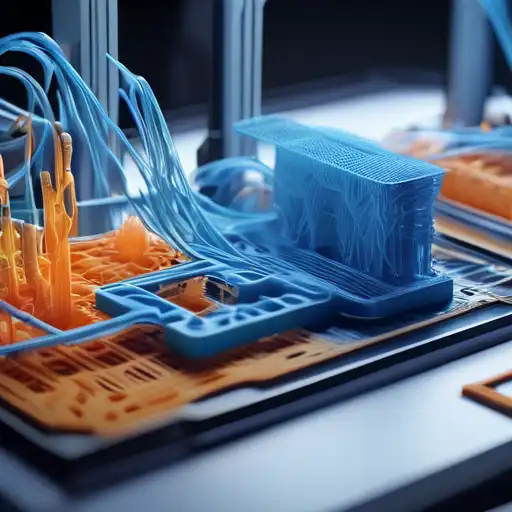

At its core, 3D printing involves creating a three-dimensional object from a digital file. The process starts with designing a model using computer-aided design (CAD) software. This model is then sliced into thin layers by the printer's software, guiding the printer to deposit material layer by layer until the object is fully formed. Materials used can range from plastics and metals to ceramics and even biological materials, opening up endless possibilities.

The Benefits of 3D Printing

3D printing offers numerous advantages over traditional manufacturing methods. These include:

- Customization: Products can be easily customized without the need for expensive molds or tooling.

- Speed: From design to production, 3D printing can significantly reduce the time it takes to bring a product to market.

- Cost-Effectiveness: For small production runs, 3D printing can be more cost-effective than traditional methods.

- Sustainability: Additive manufacturing produces less waste by using only the material needed to create the object.

Applications of 3D Printing

The applications of 3D printing are vast and varied, spanning across industries such as healthcare, aerospace, automotive, and fashion. In healthcare, for example, 3D printing is used to create custom prosthetics and even bioprint tissues. The aerospace industry utilizes 3D printing to produce lightweight components that reduce fuel consumption. Meanwhile, in the automotive sector, companies are printing parts on demand, streamlining inventory and reducing costs.

Challenges and Future Directions

Despite its many benefits, 3D printing faces challenges such as material limitations, production speed, and the need for post-processing. However, ongoing research and development are addressing these issues, paving the way for more advanced applications. The future of 3D printing includes the potential for printing electronics, more sustainable materials, and even buildings, further solidifying its role in shaping the future.

As we continue to explore the possibilities of 3D printing, it's clear that this technology is not just about creating objects but about reimagining the way we design, manufacture, and think about production. The layer-by-layer approach of 3D printing is indeed creating the future, one layer at a time.